Development and Applications

M&B MAG is an exclusive manufacturer of aluminum frames and other metal components for TEMS under license from the Canadian Department of National Defence.

The Tent Expandable Modular Systems (TEMS) have had more than 40 years of development and detail improvement. Over the years TEMS proved to be one of the most versatile multipurpose tent systems that has a wide range of uses: from a basic tent (for workspace, storage, temperate accommodation) to an insulated partitioned administrative complex.

TEMS Design

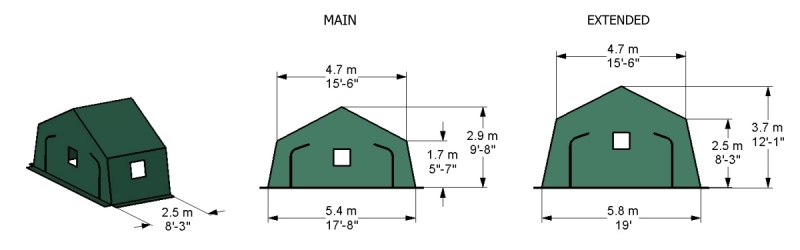

The sections of tent which comprise the modules come in two sizes: the Main type and the 0.75 m higher Extended.

The size and shape of the tent profile have an element of international conformity. They are governed by the stress imposed on the standard Ø1.9” (5 cm) aluminum tubing that comprises the framework. The tents are self-supporting and free of guy lines. Modules are in increments of 8’-3” (2.5 m) long.

A single module consists of the canvas sections covering for the roof, front and rear sides of the tent, and two arch frames with three purlins. An additional module requires a single additional arch assembly with a set of purlins.

Simplicity of Installation

The equipment is self-explanatory: no training required to install it, apart from rudimentary knowledge of the ‘Dutch lacing’ attachment method. The canvas does not have any structural tensioning and may be rolled or removed at will. The rugged aluminum frame arch simply unfolds and the three purlins which span the length of a module are inserted by hand and held by cast metal latches. The frame skeleton is made rigid by quick-buckle tensioning straps.

Though not recommended, it has been known for one person to single-handedly pitch a large complex. For an installation crew, generally one person is required per arch. Long rows of modules can be raised progressively.